- APS brake discs are machined and then put through a proprietary heat treating process that strengthens the steel by bonding the carbon, oxygen, and nitrogen in the top layer of the metal

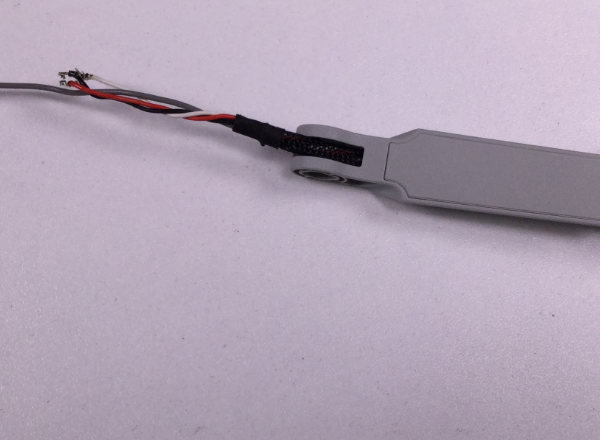

- The metallic (adherent) and semi-metallic/organic (abrasive) brake linings utilize the latest in friction material technology, using Kevlar fibers for bonding, which increases service life and durability without changing the coefficient of friction required for proper braking performance

- We have used Lining retaining pins on various metallic brake linings and have used rivets on various organic brake linings

APS brake discs are state-of-the-art CNC machined from a one-piece forging

When the metal is forged it creates a directional grain flow that follows the contour of the disc. This allows for a much stronger disc that has a reduced risk of the cracking and catastrophic failures associated with the inferior welded design.

Advantages:

Our proprietary heat treatment has a two-fold purpose. The heat treatment strengthens the steel by bonding the carbon, oxygen, and nitrogen in the top layer of the metal. This is not a coating that can wear off. We have transformed the steel. The heat treatment gives the steel its aesthetically pleasing black appearance and provides a surface with a high resistance to the corrosion and oxidation associated with the extreme thermal cycling experienced in aircraft braking systems. This makes it an excellent choice for agricultural aircraft that work in a harsh, chemical environment, as well as anyone who leaves their plane outside for most of its life.

The performance of Kevlar™

We have impregnated APS semi-metallic linings with Kevlar® fibers for optimum performance.

We have constructed APS metallic linings from an innovative design and from more durable materials than other brands. Because of that you get longer wear and superior stopping power for greater safety.

APS brake discs are a good value

APS discs and linings generally cost less. When you consider the cost savings alongside the longer life, APS BlackSteel® discs and linings are a value you just won’t find anywhere else.

APS has a high standard of quality

In order to receive FAA PMA certification, APS brake discs and linings must go through a rigorous testing process.

All APS brakes must meet or exceed OEM standards. In every case of testing APS, brakes exceeded the required standards for performance and reliability. Lastly, we have tested APS discs and linings as part of the PMA approval process.

There are no reviews yet.